Basic Info.

Model NO.

0.5mm 0.6mm 0.7mm 0.8mm 0.9mm 1mm

Surface Treatment

2b Ba Sb 1d 2D No.4 Mirror 8K Hairline Ti-Gloden

Certificate of Origin

Available

Width

1000 1200 1219 1500 mm

Length

2000 2440 3000 6000 mm

Transportation

by Sea Air Train

Brand

Tisco Baosteel Lisco

Finish

Brushed Polished Ba Ti-Golden Blue Rose

Thickness

0.4mm 0.5mm 0.6mm 0.7mm 0.8mm 1.0mm 1.5mm 1.2mm

Color

Mirror, Rose, Blue, Ti-Golden, Copper

Transport Package

Standard Sea-Worthy Packing

Specification

1.0mm 1.2mm 1.5mm 2.0mm 2.5mm 3.0mm 4.0mm 5.0mm

Trademark

Std-steel

Origin

Tianjin China

HS Code

7219900000

Production Capacity

2000ptm

Product Description

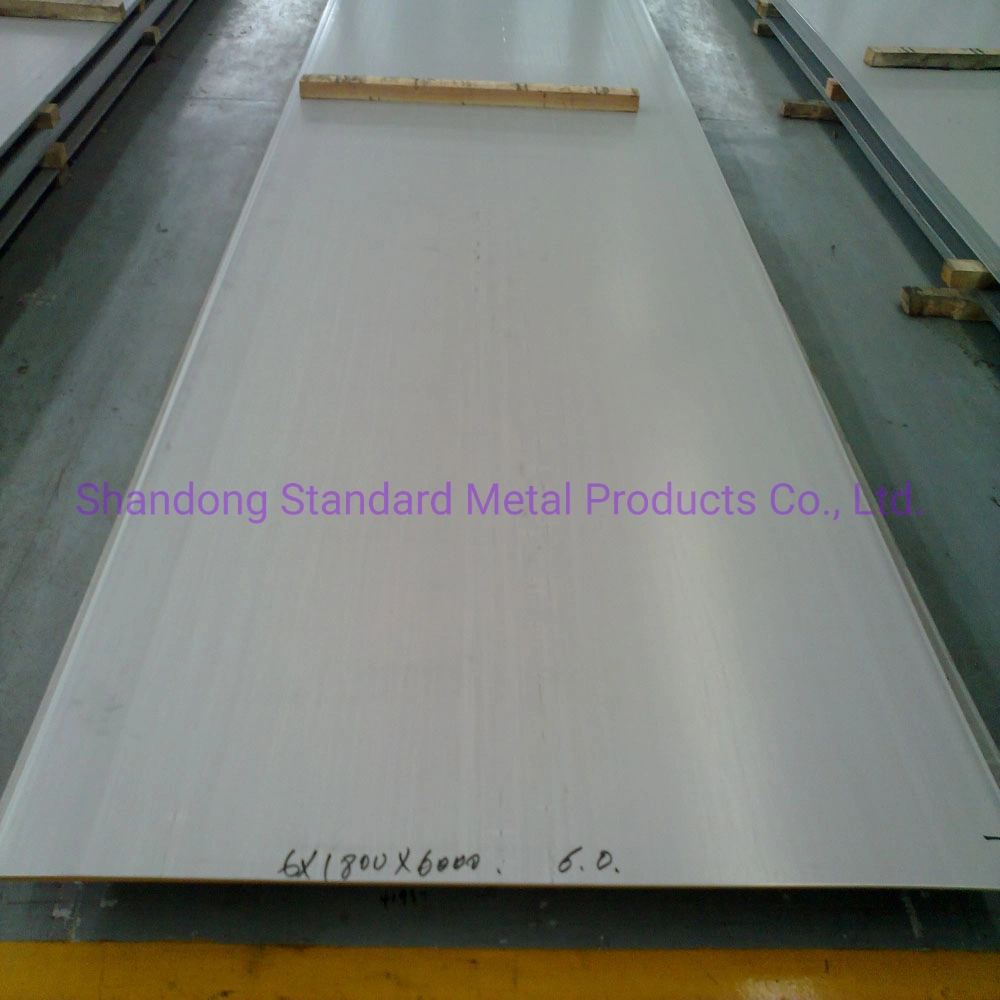

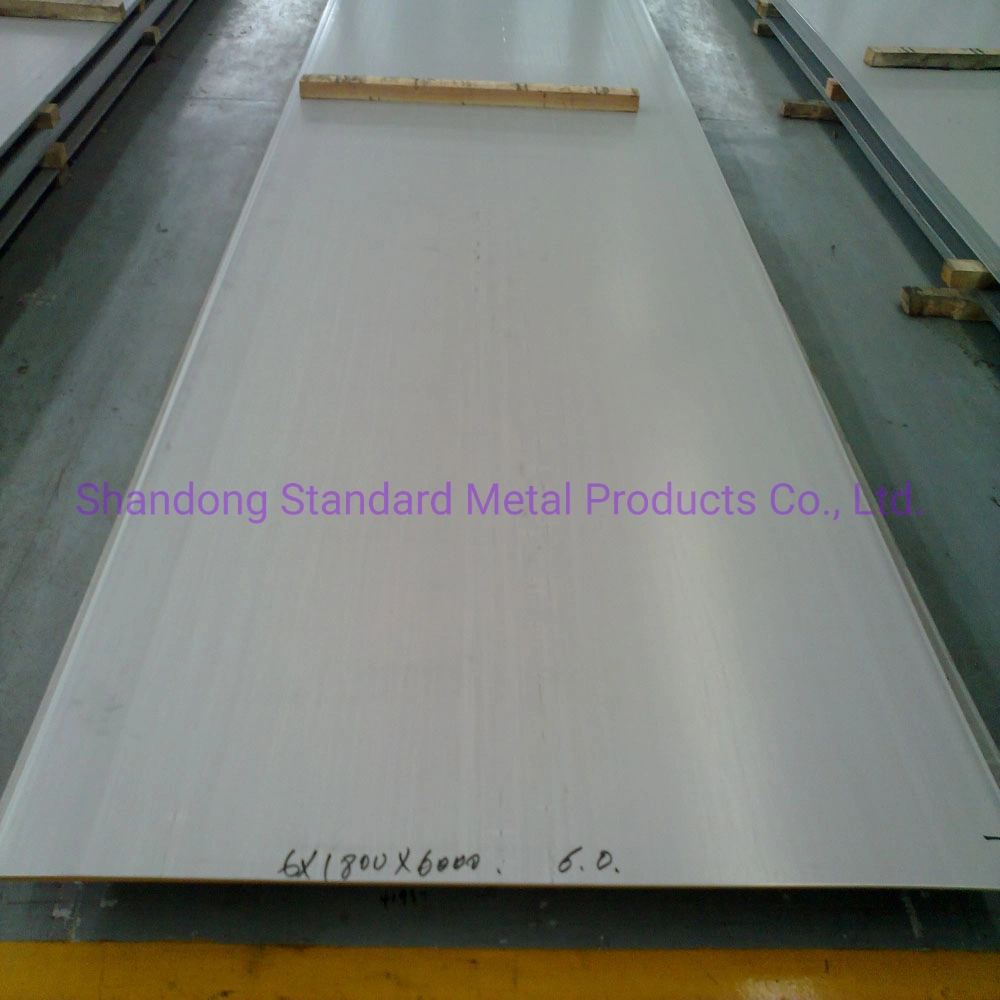

AISI 304 Stainless Steel Sheet/Plate (BA / No. 4 / No. 8 / Hl Hairline / Mirror) 1.4301

1) Types 304 austenitic stainless steels provide useful resistance to corrosion on a wide range of moderately oxidizing to moderately reducing environments. The alloys are used widely in equipment and utensils for processing and handling of food, beverages and dairy products. Heat exchangers, piping, tanks and other process equipment in contact with fresh water also utilize these alloys. Building facades and other architectural and structural applications exposed to non marine atmospheres also heavily utilize the 18-8 alloys. In addition, a large variety of applications involve household and industrial chemicals.

2). Specification:

Standard: ASTM AISI SUS JIS EN DIN

TK-cold rolled: 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 1.0, 1.2, 1.5, 2.0, 3.0, 4.0, 5.0mm

-hot rolled: 3.0, 4.0, 5.0, 6.0, 8.0, 10 ,18, 20 ...70mm 80mm or as requirement

Width x Length : 4" x 8" , 5" x 10" , 5" x 20" , 1200 x 2400mm,

We can customize for you as your requirements.

3). Surface finish: 2D , 2B ,2F , BA , HL , MIRROR , BRUSHED, NO.4 , NO.8

Surface protection: PVC coated, paper interleave, anti-fingerprint

Finish 2B, Finished by heat treatment, pickled after cold rolling, followed by skin pass line to be brighter and smooth. It is the standard surface with improved mechanical properties.

No 2D Finish

A no. 1 Finish after being Cold Rolled, Annealed, Pickled and Passivated. This results in a uniform dull matt finish, superior to a No. 1 Finish.

Suitable for industrial application, and eminently suitable for severe deep drawing as the dull surface, (which may be polished after fabrication) retains the lubricant during the drawing operation.

No. BA Finish

This is more commonly referred to as a BRIGHT ANNEALED (BA) FINISH. Material with a No. 1 finish is Cold Rolled using highly polished rolls in contact with the steel surface. This smooths and brightens the surface.

The smoothness and reflectiveness of the surface improves as the material is rolled to thinner and thinner sizes. Any annealing which needs to be done in order to effect the required reduction in gauge, and the final anneal, is effected in a very closely controlled inert atmosphere. No oxidation or scaling of the surface therefore occurs and there is no need for additional pickling and passivating.

The final surface developed can have "MIRROR" type finish similar in appearance to the highly polished No. 7 and No. 8 Finishes.

4). Technology: Cold rolled/hot rolled

5). Quality: Prime quality

6). Weight of coil: As per actually calculation

Incoterm :

1. Payment terms : T/T ;

2. Port of shipment : Tianjin Xingang port , Shanghai port , Qingdao port ;

3. Delivery time : 15 days ;

4. Package : Iron belt fix ,load in container or bulk ;

Our advantage:

Δ We have our professional international trade team , we can deliver the cargo on time as per the contract ; and settle the issues arising during the transportation promptly ;

Δ Good cooperation with reputation miller , the good quality can be well guaranteed

Δ Provide good after-sale service , we can assign the worker to install the

equipment at your site ; if the cargo is damage after reach to your company ,we can settle the problem at the first time ;

Δ We will guarantee the quality for our client from beginning to the end .

How to make the order ?

Δ First step , Please contact with our sales team , talked about the cargo details , if need sample , we can supply the sample for free ;

Δ If the sample can reach to requirement , the client can sign the contract with our company;

Δ Before shipment , client can inspect the cargo loading and seal the container , we also can accept inspection of the third party ( Such as SGS ,BV etc ) ;

Δ After 5 days of shipment , we will send the documents of customs clearance to you ;

Δ After get the cargo , please give feedback to us ;

1) Types 304 austenitic stainless steels provide useful resistance to corrosion on a wide range of moderately oxidizing to moderately reducing environments. The alloys are used widely in equipment and utensils for processing and handling of food, beverages and dairy products. Heat exchangers, piping, tanks and other process equipment in contact with fresh water also utilize these alloys. Building facades and other architectural and structural applications exposed to non marine atmospheres also heavily utilize the 18-8 alloys. In addition, a large variety of applications involve household and industrial chemicals.

| GRADE | DESIGNATION | Mechanical properties | Chemical composition | ||||||||||

| EN | AISI/ ASTM | Y.S (MPa) min | T.S (MPa) | Elongation (%)min | HB (Max) | C | Cr | Ni | Mo | Mn | N | Others | |

| AUSTENITIC | 1.4372 | 201 | 330 | 750 to 950 | 40 | 241 | <=0.15 | 16,00 to18,00 | Max 1.00 | 5,50 to 7,50 | 0.05 to 0.25 | ||

| 1.4373 | 202 | 320 | 600 to 880 | 35 | 241 | <=0.15 | 17,00 to19,00 | 4.00 to 6.00 | 7,50 to 10,50 | 0.05 to 0.25 | |||

| 1.4310 | 301 | 250 | 600 to 950 | 40 | 217 | 0.05 to 0.15 | 16,00 to18,00 | 6.00 to 8.00 | <=2.00 | <=0.11 | |||

| 1.4305 | 303 | 190 | 500 to 700 | 35 | ≤0.10 | 17,00 to19,00 | 8.00 to10.00 | ≤2.00 | ≤0.11 | ||||

| 1.4301 | 304 | 210 | 520 to 720 | 45 | 149 | ≤0.07 | 17.50 to19.50 | 8.00 to10.50 | <=2.00 | ≤0.11 | |||

| 1.4306 | 304L | 200 | 500 to 700 | 45 | 143 | ≤0.030 | 18.00 to 20.00 | 10.00 to12.00 | ≤2.00 | ≤0.11 | |||

| 1.4303 | 305 | 220 | 500 to 650 | 45 | 183 | ≤0.06 | 17.00 to19.00 | 11.00 to13.00 | <=2.00 | ≤0.11 | |||

| 1.4833 | 309S | 210 | 500 to 700 | 33 | 192 | ≤0.15 | 22.00 to 24.00 | 12.00 to 14.00 | ≤2.00 | ≤0.11 | |||

| 1.4845 | 310S | 210 | 500 to 700 | 33 | 192 | ≤0.10 | 24.00 to 26.00 | 19.00 to 22.00 | <=2.00 | ≤0.11 | |||

| 1.4841 | 314 | 230 | 550 to 750 | 28 | 223 | ≤0.20 | 24.00 to 26.00 | 19.00 to 22.00 | ≤2.00 | ≤0.11 | |||

| 1.4401 | 316 | 220 | 530 to 730 | 40 | 149 | ≤0.07 | 16.50 to 18.50 | 10.00 to 13.00 | 2.00 to 2.50 | <=2.00 | ≤0.11 | ||

| 1.4406 | 316L | 220 | 520 to 670 | 45 | 146 | ≤0.030 | 16.50 to 18.50 | 10.00 to 13.00 | 2.00 to 2.50 | ≤2.00 | ≤0.11 | ||

| 1.4571 | 316TI | 220 | 520 to 670 | 40 | 217 | ≤0.08 | 16.50 to 18.50 | 10.50 to 13.50 | 2.00 to 2.50 | <=2.00 | ≤0.11 | Ti:5×c-0.70 | |

| 1.4438 | 317L | 220 | 520 to 720 | 40 | 217 | ≤0.030 | 17.50 to 19.50 | 13.00 to 16.00 | 3.00 to 4.00 | ≤2.00 | ≤0.11 | ||

| 1.4541 | 321 | 200 | 500 to 700 | 40 | 160 | ≤0.080 | 17.00 to19.00 | 9.00 to 12.00 | <=2.00 | Ti:5×c-0.70 | |||

| 1.4550 | 347 | 200 | 500 to 700 | 40 | 160 | ≤0.080 | 17.00 to19.00 | 9.00 to 12.00 | ≤2.00 | Nb:10×c-1.0 | |||

| 1.4539 | 904L | 220 | 520 to 720 | 35 | ≤0.020 | 19.00 to21.00 | 24.00 to 26.00 | 4.00 to 5.00 | ≤2.00 | ≤0.11 | Cu:1.20 to 2.00 | ||

| DUPLEX | 1.4462 | 2205 | 460 | 640 to 840 | 25 | 293 | ≤0.030 | 21.00 to23.00 | 4.50 to 6.50 | 2.50 to 3.50 | ≤2.00 | 0.10 to 0.22 | |

| 1.4362 | 2304 | 400 | 630 to 800 | 20 | 290 | ≤0.030 | 22.00 to24.00 | 3.50 to 5.50 | 0.10 to 0.60 | ≤2.00 | 0.05 to 0.20 | Cu:0.10 to 0.60 | |

| 1.4410 | 2507 | 530 | 730 to 930 | 15 | 310 | ≤0.030 | 24.00 to26.00 | 6.00 to 8.00 | 3.00 to 4.50 | ≤2.00 | 0.24 to 0.35 | ||

| 1.4507 | 255 | 530 | 730 to 930 | 25 | 302 | ≤0.030 | 24.00 to 26.00 | 6.00 to 8.00 | 3.00 to 4.00 | ≤2.00 | 0.20 to 0.30 | Cu:1.00 to 2.50 | |

| FERRITIC | 1.4512 | 409 | 220 | 380 to 560 | 25 | 160 | ≤0.030 | 10.50 to12.50 | ≤1.00 | Ti:6×(c+N) to 0.65 | |||

| 1.4016 | 430 | 260 | 430 to 630 | 18 | ≤0.080 | 16.00 to 18.00 | ≤1.00 | ||||||

| 1.4113 | 434 | 280 | 450 to 630 | 18 | ≤0.080 | 16.00 to 18.00 | ≤1.00 | 0.90 to 1.40 | |||||

| 1.4521 | 444 | 300 | 420 to620 | 20 | 217 | ≤0.025 | 17,00 to22,00 | 1.80 to 2.50 | ≤1.00 | ≤0.030 | Ti:4×(c+N)+0.15 to 0.80 | ||

| 1.4749 | 446 | 280 | 500 to 700 | 13 | 212 | 0.15 to 0.20 | 26.00 to 29.00 | ≤1.00 | 0.15 to 0.25 | ||||

| MATENSITIC | 1.4006 | 410 | 205 | max 600 | 20 | 200 | 0.08 to 0.15 | 11.50 to 13.50 | ≤0.75 | ≤1.50 | |||

| 1.4021 | 420 | 345 | max 700 | 15 | 225 | 0.16 to 0.25 | 12.00 to 14.00 | ≤1.50 | |||||

Standard: ASTM AISI SUS JIS EN DIN

TK-cold rolled: 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 1.0, 1.2, 1.5, 2.0, 3.0, 4.0, 5.0mm

-hot rolled: 3.0, 4.0, 5.0, 6.0, 8.0, 10 ,18, 20 ...70mm 80mm or as requirement

Width x Length : 4" x 8" , 5" x 10" , 5" x 20" , 1200 x 2400mm,

We can customize for you as your requirements.

3). Surface finish: 2D , 2B ,2F , BA , HL , MIRROR , BRUSHED, NO.4 , NO.8

Surface protection: PVC coated, paper interleave, anti-fingerprint

Finish 2B, Finished by heat treatment, pickled after cold rolling, followed by skin pass line to be brighter and smooth. It is the standard surface with improved mechanical properties.

No 2D Finish

A no. 1 Finish after being Cold Rolled, Annealed, Pickled and Passivated. This results in a uniform dull matt finish, superior to a No. 1 Finish.

Suitable for industrial application, and eminently suitable for severe deep drawing as the dull surface, (which may be polished after fabrication) retains the lubricant during the drawing operation.

No. BA Finish

This is more commonly referred to as a BRIGHT ANNEALED (BA) FINISH. Material with a No. 1 finish is Cold Rolled using highly polished rolls in contact with the steel surface. This smooths and brightens the surface.

The smoothness and reflectiveness of the surface improves as the material is rolled to thinner and thinner sizes. Any annealing which needs to be done in order to effect the required reduction in gauge, and the final anneal, is effected in a very closely controlled inert atmosphere. No oxidation or scaling of the surface therefore occurs and there is no need for additional pickling and passivating.

The final surface developed can have "MIRROR" type finish similar in appearance to the highly polished No. 7 and No. 8 Finishes.

4). Technology: Cold rolled/hot rolled

5). Quality: Prime quality

6). Weight of coil: As per actually calculation

| commodity | AISI 304 stainless steel/plate(finish 2B/BA/2D) |

| material | 201, 202, 304, 304L, 316, 316L, 309S, 310S, 317L, 321, 409, 409L, 410, 420, 430, etc |

| surface | 2B, BA, HL, 4K, 6K, 8KNO. 1, NO. 2, NO. 3, NO. 4, NO. 5, and so on |

| standard | AISI, ASTM, DIN, EN, GB, JIS, etc |

| specification | (1) thickness: 0.3mm- 100mm (2) width: 1000mm, 1250mm, 1500mm, 1800mm, 2000mm, etc (3) length: 2000mm2440mm, 3000mm, 6000mm, etc (4) The specifications can be provided as clients' requirement. |

| application | (1) Construction, decoration (2) petroleum, chemical industry (3) electrical appliances, automotive, aerospace (4) house ware, kitchen appliances, cutlery, foodstuff (5) surgical instrument |

| advantage | (1) High surface quality, clean, smooth finish (2) Good corrosion resistance, durability than ordinary steel (3) High strength and to deform (4) Not easy to be oxidized (5) Good welding performance (6) The use of diversity |

| package | (1) Products are packed and labeled according to regulation (2) According to customers' requirement |

| delivery | within 20 working days since we get the deposit, mainly according to your quantity and the ways of transportation. |

| payment | T/T, L/C |

| shipment | FOB/CIF/CFR |

| productivity | 500tons/month |

| note | We can supply other grade products as customers' requirement. |

1. Payment terms : T/T ;

2. Port of shipment : Tianjin Xingang port , Shanghai port , Qingdao port ;

3. Delivery time : 15 days ;

4. Package : Iron belt fix ,load in container or bulk ;

Our advantage:

Δ We have our professional international trade team , we can deliver the cargo on time as per the contract ; and settle the issues arising during the transportation promptly ;

Δ Good cooperation with reputation miller , the good quality can be well guaranteed

Δ Provide good after-sale service , we can assign the worker to install the

equipment at your site ; if the cargo is damage after reach to your company ,we can settle the problem at the first time ;

Δ We will guarantee the quality for our client from beginning to the end .

How to make the order ?

Δ First step , Please contact with our sales team , talked about the cargo details , if need sample , we can supply the sample for free ;

Δ If the sample can reach to requirement , the client can sign the contract with our company;

Δ Before shipment , client can inspect the cargo loading and seal the container , we also can accept inspection of the third party ( Such as SGS ,BV etc ) ;

Δ After 5 days of shipment , we will send the documents of customs clearance to you ;

Δ After get the cargo , please give feedback to us ;